Introduction

Lean Six Sigma (LSS) has long been associated with manufacturing, but its principles extend far beyond the factory floor. From healthcare to finance, IT to customer service, organizations across various industries leverage Lean Six Sigma to enhance efficiency, reduce waste, and improve quality.

In this article, we’ll explore how Lean Six Sigma is revolutionizing non-manufacturing sectors, why it matters, and how businesses can implement it to drive operational excellence.

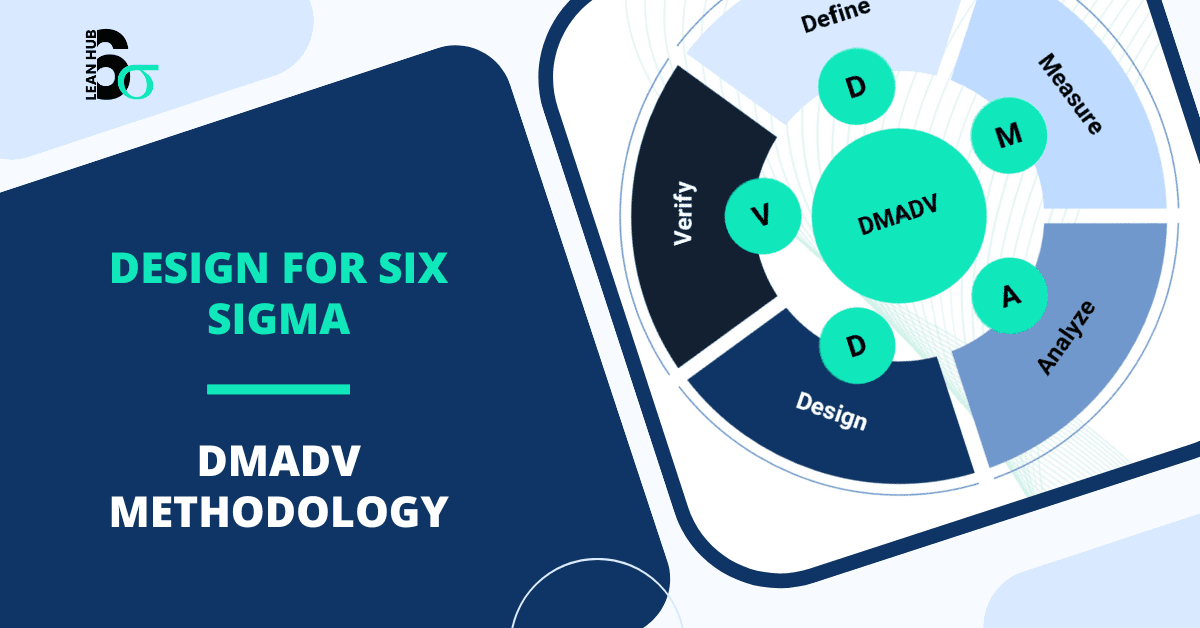

What is Lean Six Sigma?

Lean Six Sigma is a data-driven methodology that combines Lean principles (focused on waste reduction) and Six Sigma methodologies (focused on reducing process variation) to optimize business processes. The goal is to improve quality, enhance efficiency, and deliver better customer value.

Why Lean Six Sigma is Essential for Non-Manufacturing Industries

Many organizations outside of manufacturing struggle with inefficiencies, long turnaround times, high operational costs, and customer dissatisfaction. Lean Six Sigma provides a structured approach to address these challenges by:

- Reducing process inefficiencies

- Eliminating bottlenecks

- Enhancing customer experience

- Improving employee productivity

- Cutting down unnecessary costs

Industries Benefiting from Lean Six Sigma

1. Healthcare

Lean Six Sigma plays a vital role in improving patient care, reducing medical errors, and enhancing hospital operational efficiency. Applications include:

- Reducing patient wait times

- Streamlining medical billing processes

- Enhancing infection control procedures

Example: A hospital reduced patient discharge time by 35% using Lean Six Sigma, leading to better bed availability and improved patient satisfaction.

2. Financial Services & Banking

The financial industry faces issues like long processing times, compliance risks, and errors in transactions. LSS helps by:

- Streamlining loan approval processes

- Reducing transaction errors

- Enhancing fraud detection

Example: A bank implemented Lean Six Sigma to automate credit approval processes, reducing processing time from 15 days to 5 days.

3. Information Technology (IT)

In IT, Lean Six Sigma improves software development cycles, reduces downtime, and enhances system efficiency. Key benefits include:

- Faster issue resolution in IT support

- Streamlined software testing processes

- Improved project management workflows

Example: A software company used Lean Six Sigma to identify and eliminate coding inefficiencies, reducing defects by 40%.

4. Customer Service & Call Centers

Customer service teams deal with inefficiencies like long response times, high call drop rates, and inconsistent service quality. LSS helps in:

- Reducing average call handling time

- Improving first-call resolution rates

- Enhancing customer satisfaction scores

Example: A telecom company applied LSS to call center operations, cutting down average wait time by 50%.

5. Retail & E-commerce

Retailers and e-commerce businesses use Lean Six Sigma to optimize supply chains, reduce inventory waste, and enhance order fulfillment.

- Optimizing inventory management

- Reducing shipping errors

- Improving customer return processes

Example: An e-commerce giant implemented LSS to streamline warehouse operations, reducing order fulfillment time by 30%.

6. Education

Educational institutions use Lean Six Sigma to enhance administrative efficiency, improve student experiences, and reduce dropout rates.

- Streamlining admissions processes

- Reducing grading errors

- Enhancing online learning platforms

Example: A university used Lean Six Sigma to digitize student enrollment, reducing processing time from 2 weeks to 3 days.

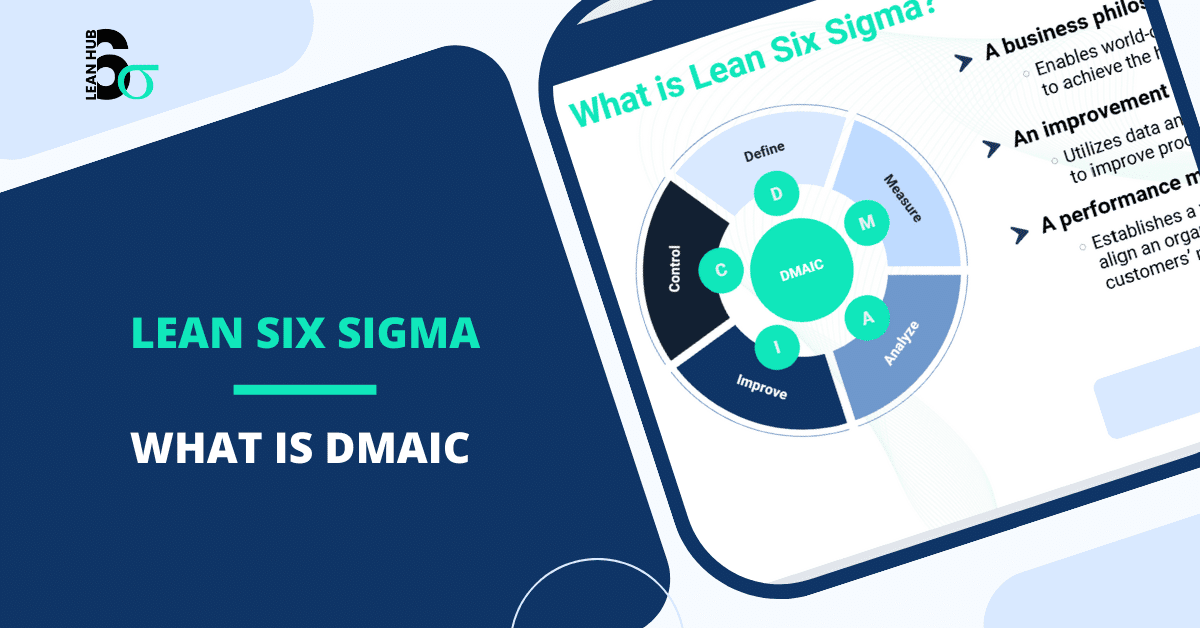

Steps to Implement Lean Six Sigma in Non-Manufacturing

1. Identify the Problem

Define the issue using data and customer feedback. Use tools like SIPOC (Suppliers, Inputs, Process, Outputs, Customers) to map out processes.

2. Measure Key Metrics

Use Key Performance Indicators (KPIs) like turnaround time, defect rates, and customer satisfaction scores to quantify inefficiencies.

3. Analyze the Root Cause

Apply techniques like Fishbone Diagrams, Pareto Charts, and 5 Whys to pinpoint the source of inefficiencies.

4. Improve the Process

Develop data-backed solutions to streamline workflows, reduce waste, and enhance customer experience.

5. Control & Sustain the Improvement

Monitor changes using Control Charts and dashboards to ensure long-term success.

Benefits of Lean Six Sigma in Non-Manufacturing

- Improved customer satisfaction

- Enhanced process efficiency

- Reduced operational costs

- Better compliance and risk management

- Increased employee productivity

Conclusion

Lean Six Sigma is not just for manufacturing—it’s a universal methodology that enhances efficiency, reduces waste, and improves customer satisfaction across various industries. Whether you’re in healthcare, finance, IT, or retail, adopting Lean Six Sigma can transform your organization’s operations.

Want to Implement Lean Six Sigma in Your Business?

Visit www.lean6sigmahub.com for expert insights, training programs, and resources to help you succeed with Lean Six Sigma!