Introduction

The integration of Lean Six Sigma with digital transformation is revolutionizing how organizations approach process improvement. By blending traditional problem-solving methodologies with cutting-edge digital technologies, businesses are achieving unprecedented efficiency, cost savings, and innovation. In this article, we explore the powerful synergy between Lean Six Sigma and digital transformation, highlighting key benefits, use cases, and steps to leverage this combination for success.

What is Lean Six Sigma?

Lean Six Sigma is a methodology designed to eliminate waste, reduce variation, and improve processes through data-driven decision-making. It incorporates:

- Lean principles: Focused on streamlining operations and reducing inefficiencies.

- Six Sigma methodologies: Centered on reducing errors and enhancing quality.

To learn more about Lean Six Sigma principles and their impact, visit Lean Six Sigma Overview.

What is Digital Transformation?

Digital transformation refers to the adoption of digital technologies to enhance operations, customer experiences, and organizational agility. Key elements include:

- Artificial Intelligence (AI)

- Machine Learning (ML)

- Robotic Process Automation (RPA)

- Internet of Things (IoT)

- Data analytics

If you’re new to Lean Six Sigma and digital transformation, check out the Introduction to Lean Six Sigma: A Comprehensive Guide for Beginners.

The Synergy Between Lean Six Sigma and Digital Transformation

Combining Lean Six Sigma and digital transformation creates a powerful force for business improvement. This integration allows companies to:

- Automate Processes:

- Replace repetitive, manual tasks with RPA to boost productivity.

- Example: Automating invoice processing to reduce cycle times and errors.

- Leverage Big Data:

- Use AI and data analytics to uncover insights and monitor performance.

- Example: Predictive analytics to forecast demand and optimize inventory.

- Enhance Customer Experiences:

- Apply Lean Six Sigma to improve processes that impact customer satisfaction.

- Example: Reducing call center wait times using automated solutions.

- Enable Real-Time Monitoring:

- Utilize IoT for continuous data collection and process improvement.

- Example: Monitoring equipment performance to prevent downtime.

Learn more about real-world applications in the DMAIC Process: A Step-by-Step Guide to Lean Six Sigma Methodology.

Key Benefits of Lean Six Sigma in Digital Transformation

- Improved Decision-Making:

- Data-driven insights from Six Sigma, combined with real-time analytics, enable precise decision-making.

- Increased Efficiency:

- Automation and AI streamline operations, eliminating waste and inefficiencies.

- Enhanced Agility:

- Organizations can respond faster to changes in market conditions or customer needs.

- Cost Savings:

- Reduced operational costs through process optimization and waste reduction.

- Scalability:

- Digital tools allow Lean Six Sigma principles to be applied at scale, across global operations.

To dive deeper into these benefits, explore the Fundamentals of Lean Six Sigma: Key Concepts and Principles.

Use Cases of Lean Six Sigma and Digital Transformation

- Manufacturing:

- Using IoT to monitor production lines and reduce defects.

- Implementing AI-driven quality control for real-time error detection.

- Healthcare:

- Streamlining patient scheduling systems with automation.

- Using data analytics to reduce hospital readmissions.

- Retail:

- Optimizing supply chain management with predictive analytics.

- Enhancing customer service through chatbots and AI-powered solutions.

- Finance:

- Automating loan approval processes for faster turnaround times.

- Reducing errors in financial reporting with RPA.

For practical examples of Lean Six Sigma applications in these sectors, check out Lean Six Sigma in Healthcare and Beyond.

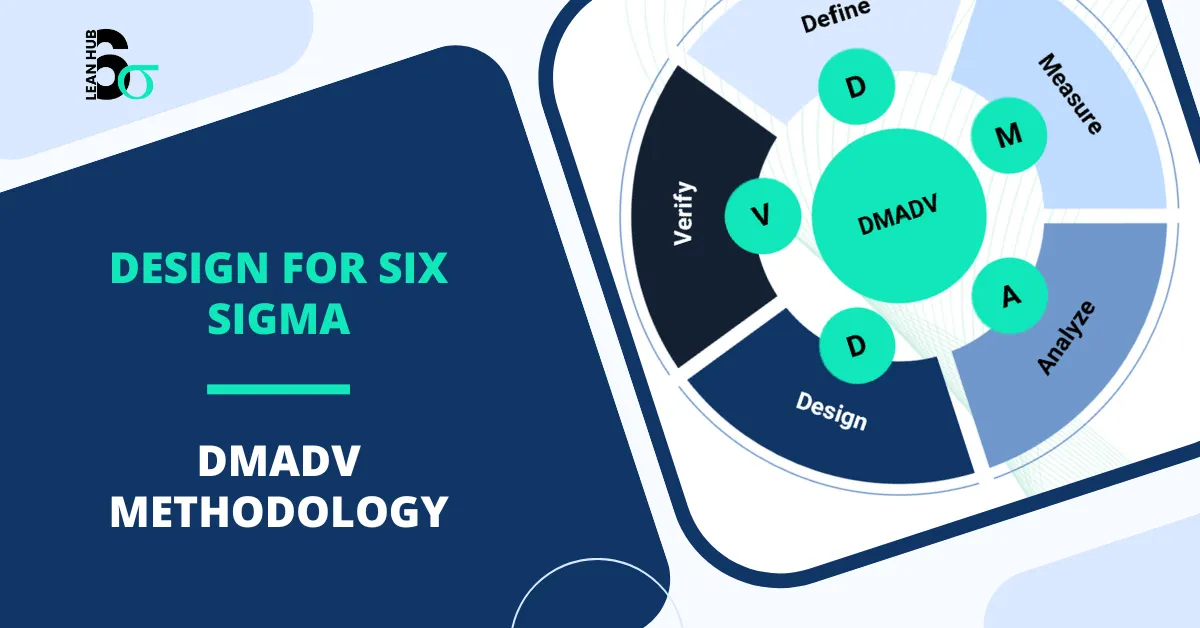

Steps to Implement Lean Six Sigma in Digital Transformation

- Define Goals:

- Identify specific business objectives, such as reducing costs or enhancing customer satisfaction.

- Assess Processes:

- Use Lean Six Sigma tools like DMAIC (Define, Measure, Analyze, Improve, Control) to evaluate current processes.

- Adopt Digital Tools:

- Select technologies (e.g., RPA, AI) that align with your process improvement goals.

- Train Teams:

- Educate employees on both Lean Six Sigma methodologies and digital tools.

- Monitor and Adjust:

- Continuously analyze results and refine strategies to maximize impact.

Conclusion

The fusion of Lean Six Sigma and digital transformation is reshaping the business landscape. By combining proven methodologies with advanced digital technologies, organizations can achieve superior efficiency, innovation, and competitiveness. Whether you’re in manufacturing, healthcare, retail, or finance, the time to embrace this synergy is now.

For more information on how Lean Six Sigma can transform your business, visit Lean Six Sigma Hub.