Introduction

Lean Six Sigma (LSS) has become a game-changer for corporates aiming for efficiency, cost reduction, and quality improvement. By combining Lean principles (eliminating waste) and Six Sigma methodologies (reducing variation), organizations can achieve operational excellence, enhance customer satisfaction, and drive sustainable growth.

1. Why Lean Six Sigma Matters in Corporates

Corporations across industries leverage Lean Six Sigma to:

– Reduce defects and rework, improving product/service quality

– Optimize operational processes to cut costs and enhance efficiency

– Boost customer satisfaction through consistent and reliable services

– Foster a culture of continuous improvement

– Improve employee productivity by eliminating non-value-added tasks

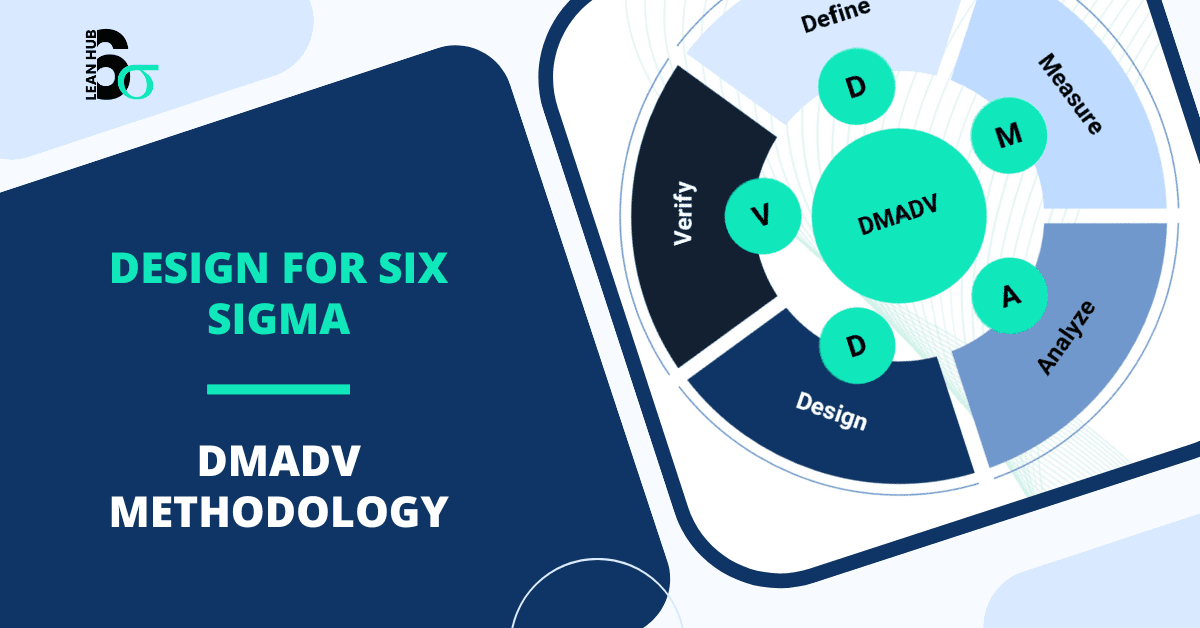

2. How to Implement Lean Six Sigma Using DMAIC

Step 1: Define

Identify the business problem, define customer requirements, and establish project goals.

Step 2: Measure

Collect data on current processes, establish baselines, and identify key metrics.

Step 3: Analyze

Identify root causes of inefficiencies using tools like Fishbone Diagram & Pareto Chart.

Step 4: Improve

Develop and implement solutions like automation, training, and system enhancements.

Step 5: Control

Monitor process improvements and implement control measures.

3. Key Tools for Lean Six Sigma in Corporates

– Process Mapping (Value Stream Map)

– Pareto Chart

– Control Charts

– Fishbone Diagram (Cause-and-Effect Analysis)

– 5S Framework

4. Real-World Data Insights & Charts

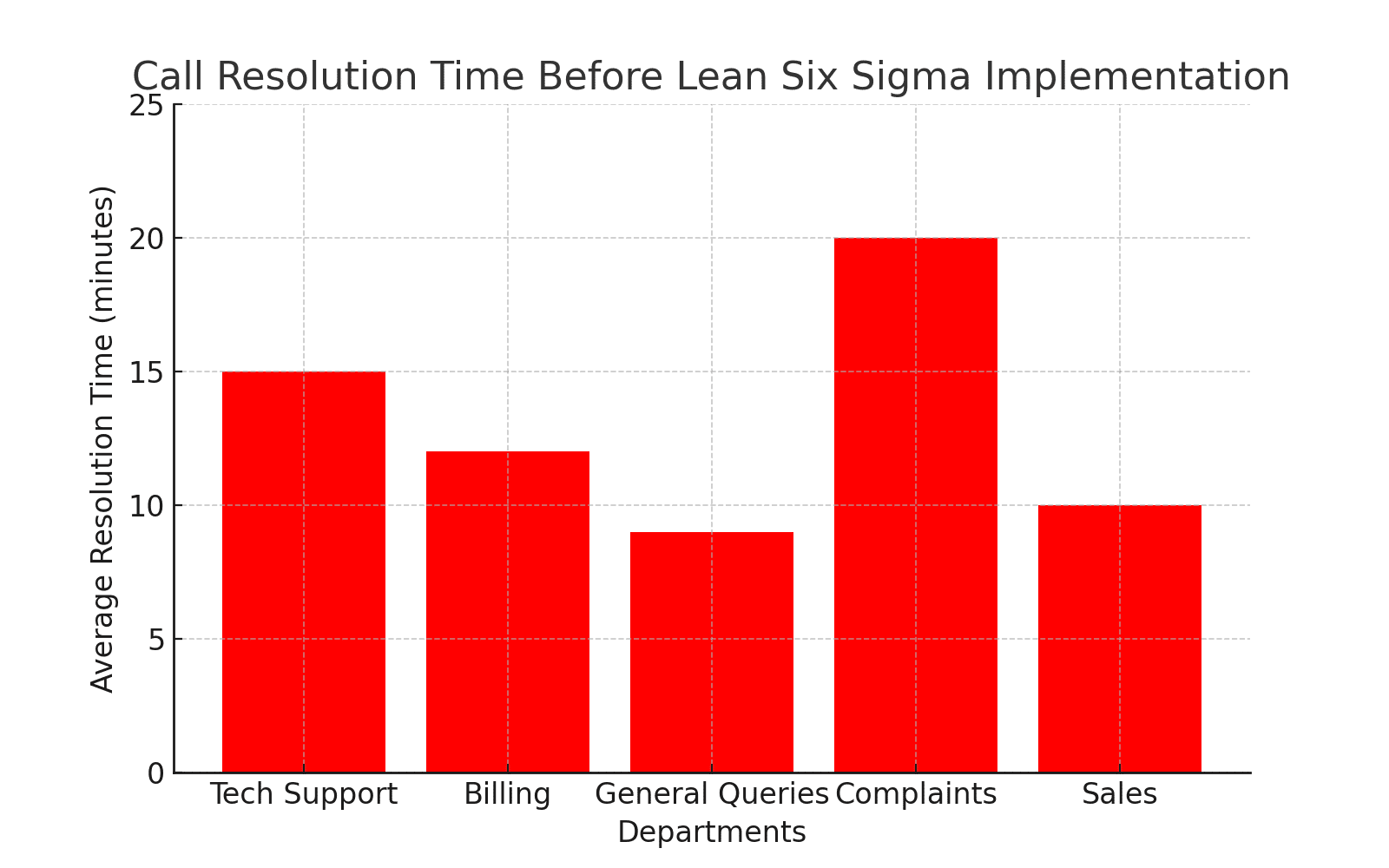

Before Lean Six Sigma Implementation

The call resolution time before implementing Lean Six Sigma was significantly high, as shown below:

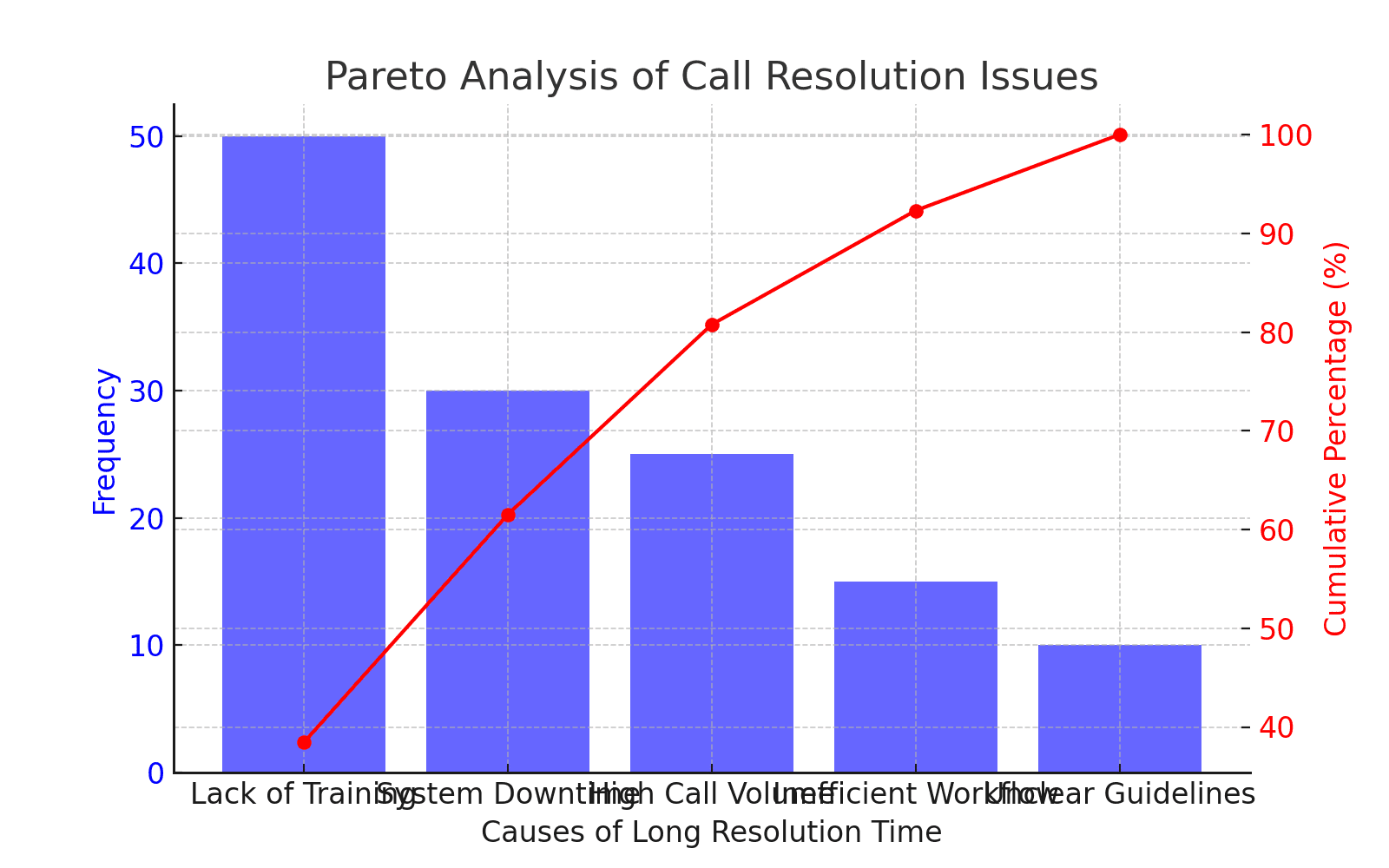

Pareto Analysis of Call Resolution Issues

This Pareto chart identifies the key issues causing long resolution times:

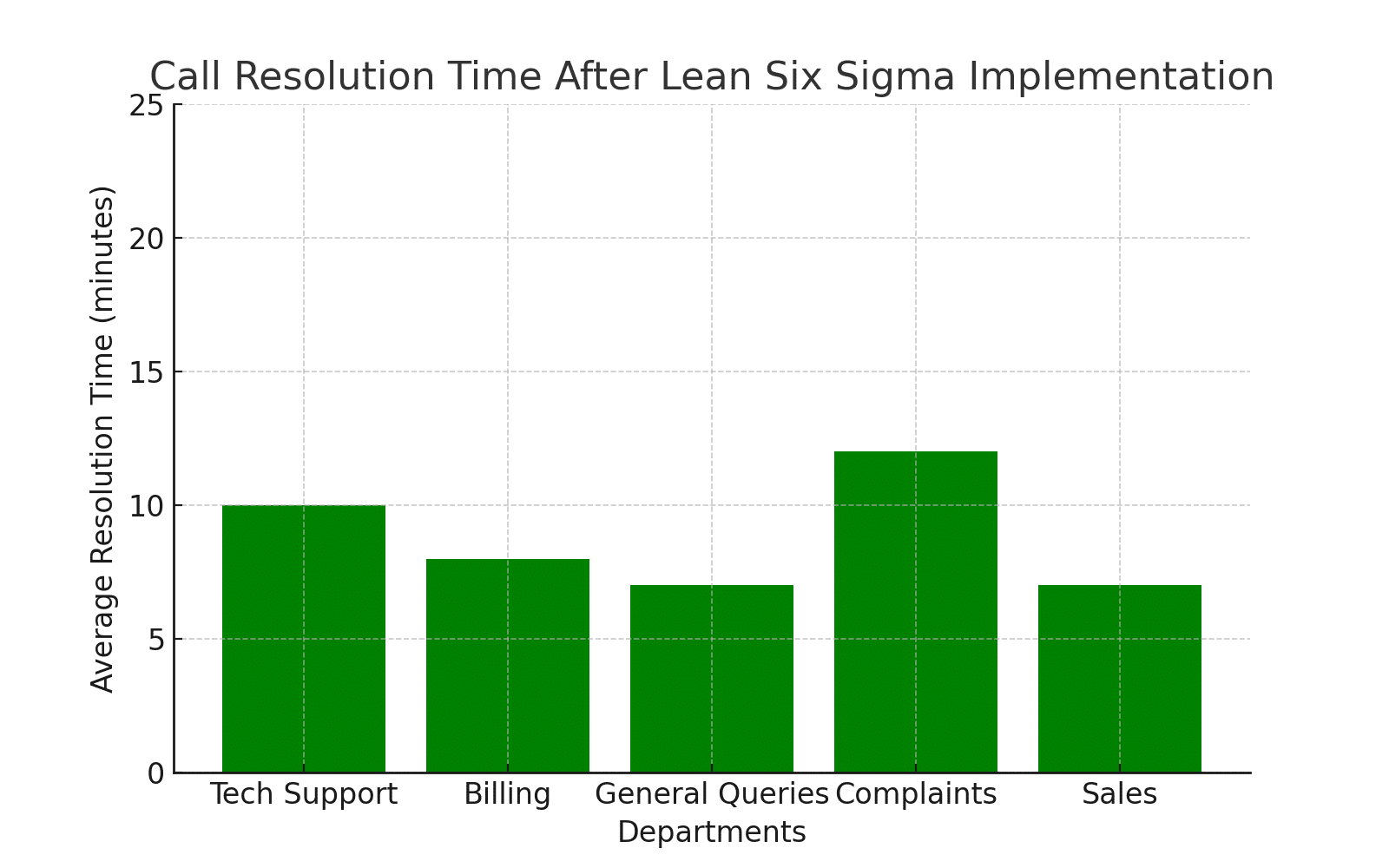

After Lean Six Sigma Implementation

After implementing Lean Six Sigma improvements, call resolution times significantly reduced:

5. Challenges & Best Practices

Common challenges in implementing Lean Six Sigma include resistance to change, lack of leadership support, poor data quality, and failure to sustain improvements. Best practices involve engaging leadership, using data-driven decisions, providing proper training, and continuous monitoring.

6. Key Takeaways

✔ Lean Six Sigma helps corporates enhance efficiency, reduce costs, and improve quality.

✔ The DMAIC methodology provides a structured approach for process optimization.

✔ Data visualization (Pareto Charts, Bar Graphs) helps identify and solve key issues.

✔ Successful implementation requires leadership commitment, proper training, and continuous monitoring.

7. Conclusion

Lean Six Sigma is a powerful framework for corporates seeking operational excellence. By eliminating waste, reducing process variations, and leveraging data-driven decision-making, businesses can enhance performance, boost customer satisfaction, and drive profitability.