Variation exists in all processes, whether manufacturing, service delivery, or business operations. While some variation is inherent and unavoidable, excessive or uncontrolled variation can lead to inefficiencies, reduced quality, and dissatisfied customers. Understanding variation and its impact is essential for optimizing processes and achieving consistent outcomes.

This guide provides a comprehensive look at variation, its types, and how to manage it effectively. Using a hypothetical scenario and dataset, we’ll demonstrate practical steps to identify, analyze, and control variation in a process.

Basics of Variation

Variation refers to the differences in process performance or outputs over time. These differences can arise from various factors, including human behavior, machine performance, materials, or environmental conditions.

Types of Variation:

- Common Cause Variation (Natural):

- Inherent in the process.

- Predictable within a specific range.

- Example: Slight differences in coffee brewing time due to water temperature fluctuations.

- Special Cause Variation (Assignable):

- Arises from unexpected factors.

- Unpredictable and often indicates a problem.

- Example: A coffee machine breaking down during peak hours.

Why Understanding Variation Matters:

- Helps identify process inefficiencies and areas for improvement.

- Enables root cause analysis to eliminate issues.

- Promotes consistency, leading to improved customer satisfaction.

Basics of Efficiency and Optimization

Efficiency and optimization aim to minimize waste, improve resource utilization, and ensure the process delivers the desired outcomes. Understanding variation is a critical step in achieving these goals.

Key Concepts:

- Process Capability: The ability of a process to produce outputs within specified limits.

- Control Limits: Statistical boundaries within which a process should operate to be considered stable.

- Standardization: Reducing variation by defining and adhering to consistent methods.

Hypothetical Scenario

A logistics company, “Swift Ship,” specializes in same-day deliveries. The company notices delays in delivery times, leading to customer complaints. Management suspects that variation in the delivery process might be the root cause of the issue.

Step 1: Define the Process and Identify Key Metrics

The first step is to understand the delivery process and identify metrics that reflect performance.

Process Steps:

- Order placement.

- Package preparation.

- Loading and dispatch.

- Delivery to the customer.

Key Metrics:

- Delivery Time (in hours): Time taken from order placement to delivery.

- Package Preparation Time (in minutes): Time spent preparing packages.

- Loading Time (in minutes): Time spent loading packages onto delivery vehicles.

Step 2: Collect Data

Swift Ship collects data on delivery times for 30 deliveries over a month. Below is the hypothetical dataset:

| Delivery ID | Delivery Time (hrs) | Package Prep Time (mins) | Loading Time (mins) |

|---|---|---|---|

| 1 | 4.2 | 25 | 15 |

| 2 | 3.8 | 20 | 10 |

| 3 | 5.0 | 30 | 20 |

| 4 | 6.5 | 40 | 25 |

| … | … | … | … |

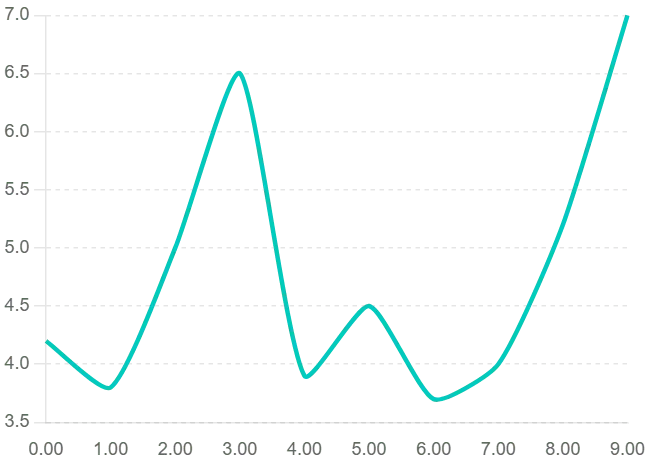

Step 3: Analyze the Data

Analyzing the data involves identifying variation in the metrics and determining whether it is caused by common or special causes.

Steps for Analysis:

- Plot Control Charts: Identify patterns in delivery times.

- Calculate Process Metrics: Compute mean, standard deviation, and range.

- Identify Outliers: Look for data points outside control limits.

Sample Findings:

- Average delivery time: 5 hours.

- Control limits: 3.5 to 6.5 hours.

- Outliers: Delivery times of 7.0 and 2.5 hours.

Step 4: Identify Sources of Variation

Once outliers are identified, the next step is to investigate their causes.

Potential Causes for Swift Ship:

- Traffic Conditions: Unpredictable delays on the road.

- Staffing Issues: Insufficient staff during peak hours causing delays in preparation or loading.

- Equipment Problems: Delivery vehicle breakdowns.

Step 5: Develop and Implement Solutions

Based on the findings, Swift Ship implements the following solutions:

- Traffic Management: Use real-time traffic monitoring tools to plan efficient routes.

- Staffing Adjustments: Increase staff during peak hours to speed up package preparation and loading.

- Vehicle Maintenance: Schedule regular vehicle maintenance to prevent breakdowns.

Step 6: Monitor and Optimize

Swift Ship continues to monitor delivery times to ensure improvements are sustained and further optimize the process where necessary.

Updated Performance Metrics (After Improvements):

| Delivery ID | Delivery Time (hrs) | Package Prep Time (mins) | Loading Time (mins) |

|---|---|---|---|

| 1 | 3.9 | 20 | 12 |

| 2 | 3.7 | 18 | 10 |

| 3 | 4.5 | 25 | 15 |

| 4 | 4.0 | 22 | 12 |

Conclusion

Understanding variation is key to achieving efficiency and optimization in any process. By distinguishing between common and special cause variation, businesses can take targeted actions to stabilize processes, improve performance, and enhance customer satisfaction.

Following the approach outlined in this guide, Swift Ship successfully reduced variation in delivery times and optimized its operations. This method can be applied to various industries to drive consistency and efficiency.