Introduction to DMADV

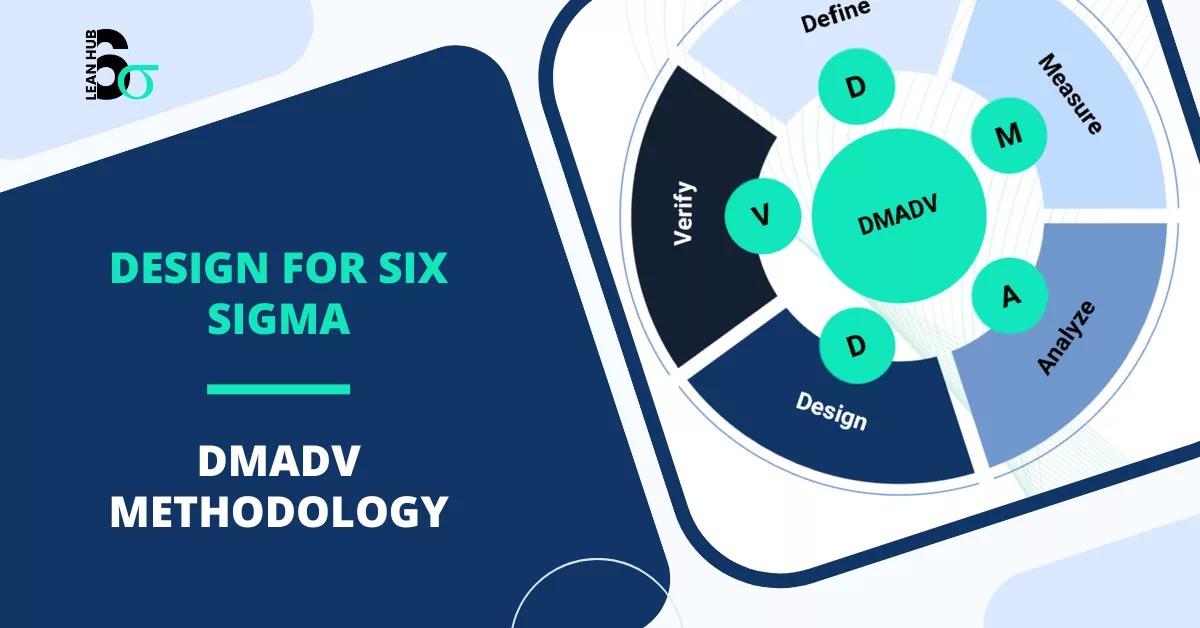

In today’s competitive marketplace, creating high-quality products and processes is not just a goal—it’s a necessity. DMADV, an acronym for Define, Measure, Analyze, Design, and Verify, is a Lean Six Sigma methodology specifically used for designing new processes or products that meet customer expectations right from the start.

Unlike DMAIC, which is used to improve existing processes, DMADV focuses on building it right the first time. This makes it especially powerful for innovation, new service rollouts, or major redesigns.

What is DMADV?

DMADV stands for:

-

Define: Establish the project goals aligned with customer demands and business strategy.

-

Measure: Identify Critical to Quality (CTQ) features, measure current capabilities, and gather customer data.

-

Analyze: Explore design alternatives, evaluate capabilities, and identify the best-fit concept.

-

Design: Develop detailed designs for the process/product, including prototypes or simulations.

-

Verify: Validate performance through testing and pilot runs, ensuring the design meets customer needs.

Each phase is backed by Lean Six Sigma tools and customer-centric thinking to ensure quality is built into the design, not added later.

DMADV vs DMAIC: What’s the Difference?

While both DMADV and DMAIC are methodologies within Lean Six Sigma, they serve different purposes:

| Feature | DMADV | DMAIC |

|---|---|---|

| Use Case | New process or product design | Improvement of existing process |

| Focus | Prevention of defects | Elimination of existing defects |

| Outcome | High-quality design from scratch | Improved existing performance |

| Final Phase | Verify the design | Control the improved process |

If you’re developing something new or the current process is fundamentally broken beyond repair, DMADV is the right choice.

When to Use DMADV

You should consider DMADV when:

-

The process or product does not exist yet.

-

Existing solutions do not meet customer needs.

-

Your organization is launching a new service or product line.

-

You want to innovate or redesign a process to align with digital transformation.

Examples include:

-

Designing a new mobile app for customer self-service.

-

Developing a streamlined onboarding process for new hires.

-

Creating a smart home device with enhanced usability.

Breaking Down the DMADV Phases

1. Define Phase

-

Identify the project purpose, scope, and high-level goals.

-

Understand customer expectations using tools like Voice of the Customer (VOC).

-

Create a high-level project charter.

2. Measure Phase

-

Define CTQs (Critical to Quality).

-

Measure customer needs quantitatively.

-

Develop measurement systems to gather relevant data.

3. Analyze Phase

-

Translate VOC into design requirements.

-

Use tools like QFD (Quality Function Deployment) and Design Failure Mode Effects Analysis (DFMEA).

-

Shortlist design concepts based on feasibility and impact.

4. Design Phase

-

Develop detailed designs with specifications.

-

Create prototypes or process maps.

-

Optimize the design using simulation or Design of Experiments (DOE).

5. Verify Phase

-

Validate the design with real-world data.

-

Conduct pilot runs or beta testing.

-

Transition the design into full-scale deployment.

Benefits of Using DMADV

✅ Reduces risk of failure by proactively addressing customer needs

✅ Builds quality into the product or process from the start

✅ Enables innovative thinking backed by structured analysis

✅ Improves customer satisfaction and competitive advantage

✅ Enhances time-to-market for new offerings

DMADV in Real-World Scenarios

Here are some real-life applications of DMADV:

-

Banking: Designing a paperless account opening process using eKYC and digital signatures.

-

Healthcare: Developing a telemedicine platform with user-friendly workflows for doctors and patients.

-

Manufacturing: Launching a new production line for electric vehicle batteries with minimal defect rates.

By starting with DMADV, these organizations avoided common pitfalls and delivered solutions that worked from day one.

Conclusion

The DMADV methodology empowers organizations to design with purpose, deliver with precision, and delight customers with high-quality solutions. Whether you’re innovating a new product, launching a service, or engineering a fresh process, DMADV ensures you do it right the first time.

Want to learn more about applying DMADV in your business?

👉 Explore Lean Six Sigma training and tools at Lean6SigmaHub.com and equip yourself or your team with the skills to design for excellence.