Six Sigma Flash Cards

Master the Lean six sigma project execution with these pdf flash cards showing hypothetical data and templates

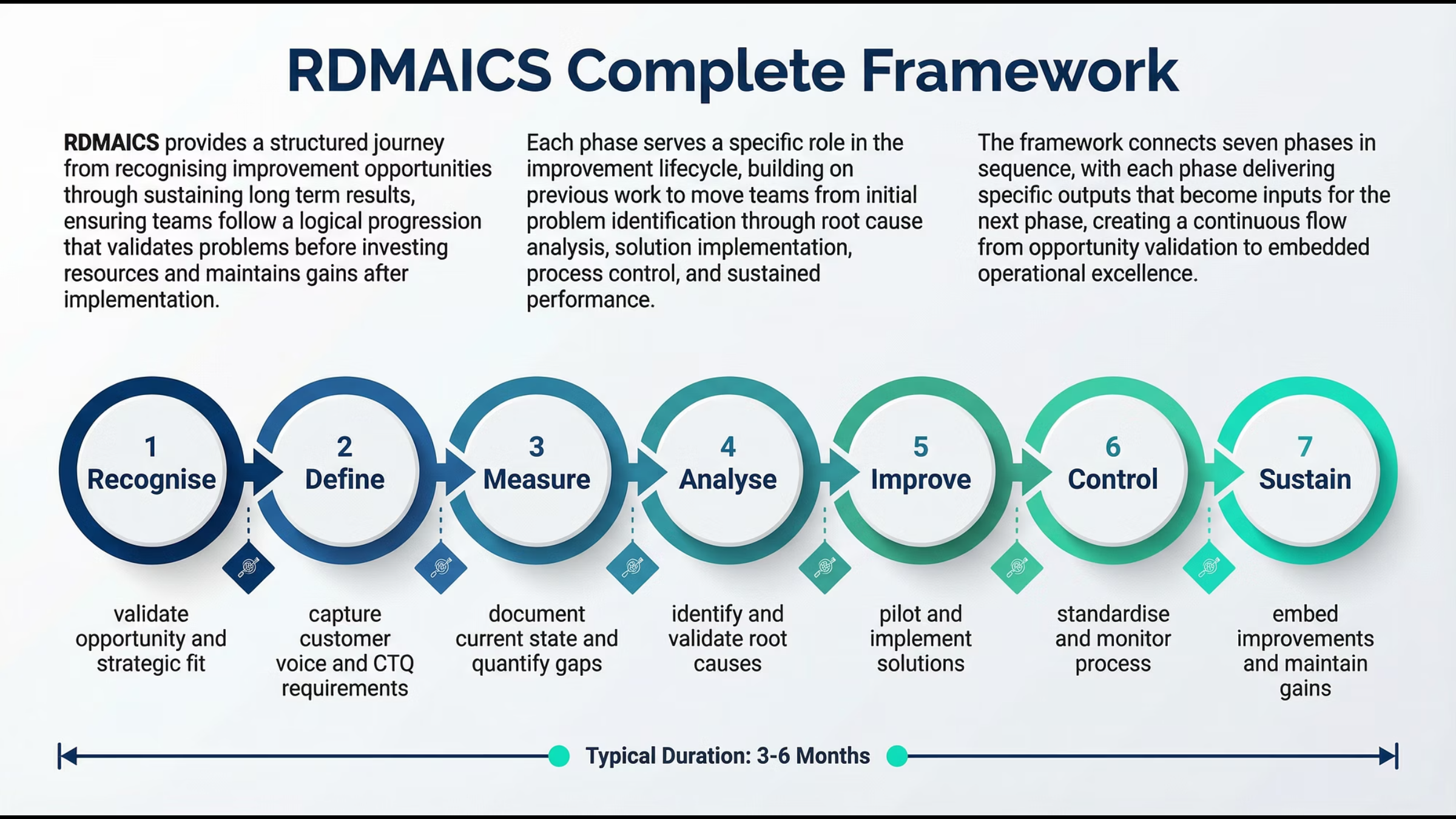

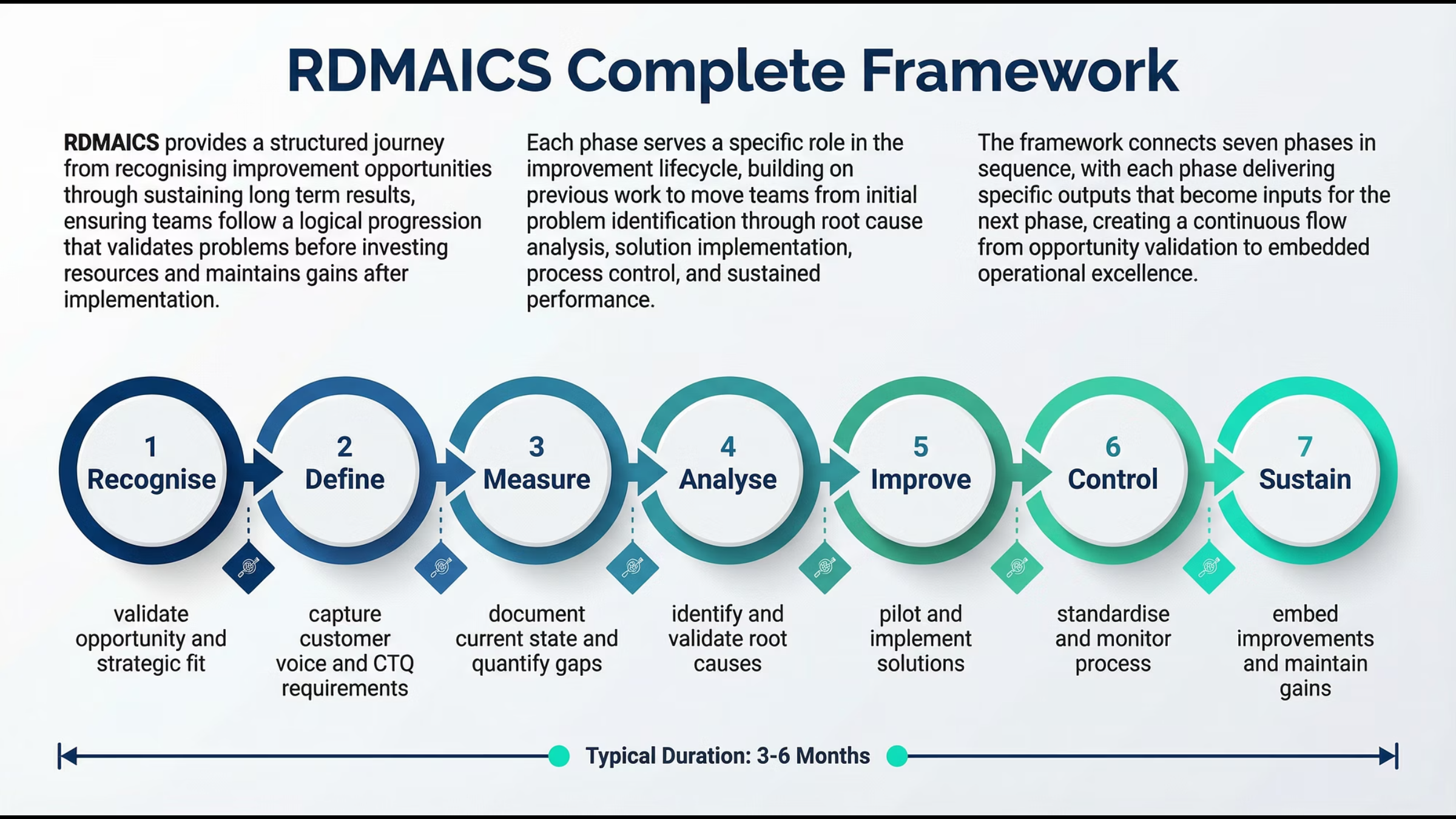

7 Phases – RDMAICS

53 Main Steps Cards

265 Substep Cards

325 Total Flash Cards

Note – Once downloaded the products are non-refundable

325 Total Flash Cards

Get the entire methodology across all seven phases from Recognise to Sustain. Every main step and substep documented on individual cards you can reference instantly during projects.

53 Main Steps

Main step cards provide overview structure with three descriptive bullets, recommended tools, and visual frameworks showing how all substeps link together in each major step.

265 Sub-step Cards

Every substep gets its own card with three actionable bullets, 4 to 8 specific tools or templates, and descriptions of actual frameworks you can build for that activity.

7 Toll Gate Reviews

Phase validation cards help you prepare for sponsor reviews, confirm completion criteria, document approval decisions, and confidently proceed to the next phase.

Practical Tools

No guessing what methods to use. Each card lists the specific tools, templates, matrices, charts, and techniques practitioners need for that exact substep.

PDF ready cards

Digital PDF works on any device. Study for certification. Reference during live projects. Train your team. Integrate into your quality system. Print copies as needed.

The Complete Seven Phase System

RDMAICS Framework Overview

Each phase includes detailed framework cards with step-by-step execution guidance, recommended tools, and visual frameworks for comprehensive process improvement.

R

Phase 1

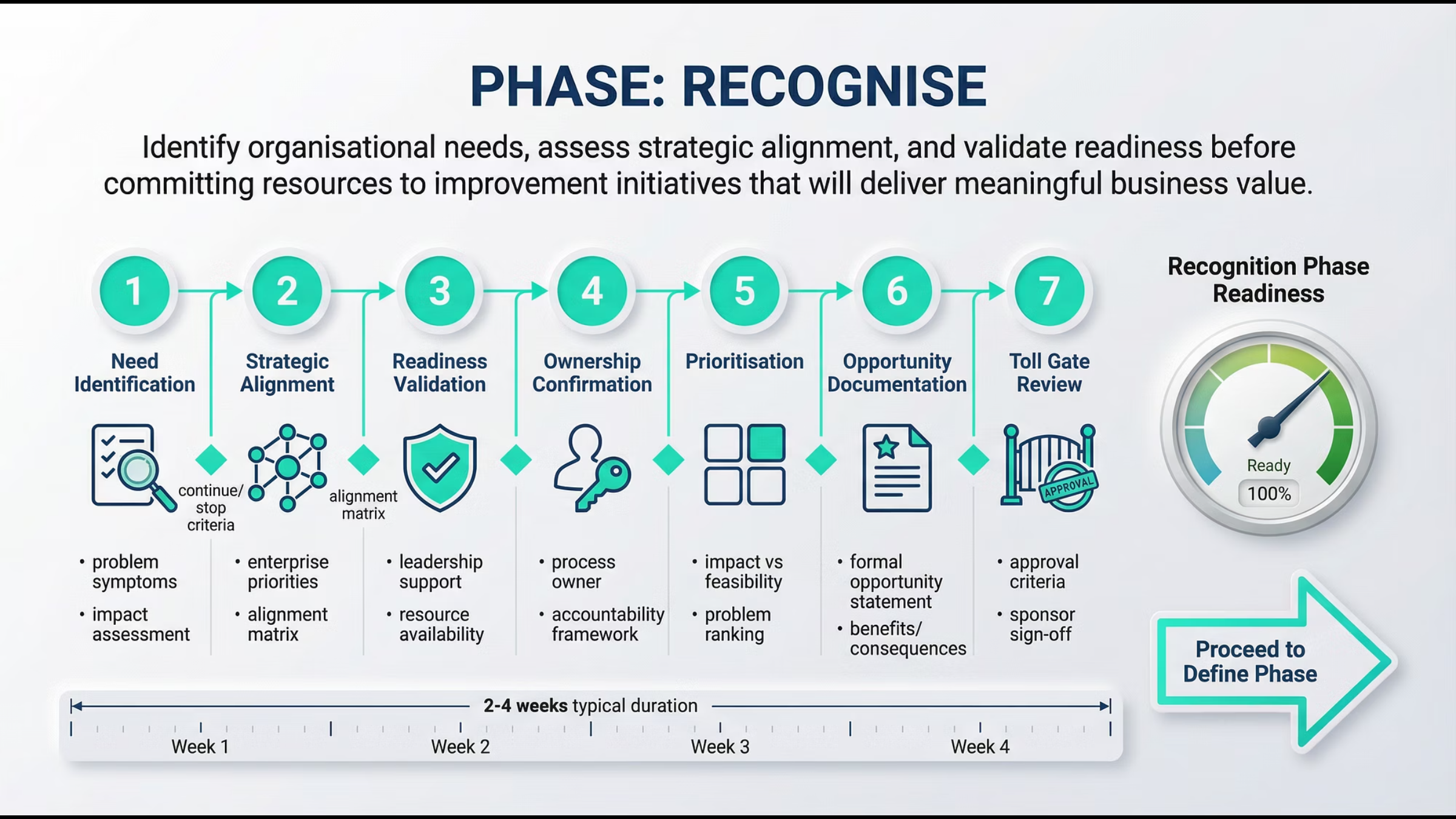

Recognise

Identify organisational needs and assess strategic alignment before committing resources. Validate readiness, confirm sponsorship, establish process ownership, and prioritise improvement opportunities.

Key Activities

-

Need Identification & Problem Symptoms

-

Strategic Alignment with Enterprise Priorities

-

Readiness Validation & Leadership Support

-

Ownership Confirmation & Accountability

-

Prioritisation & Impact Assessment

-

Opportunity Documentation

-

Toll Gate Review & Sponsor Sign-off

D

Phase 2

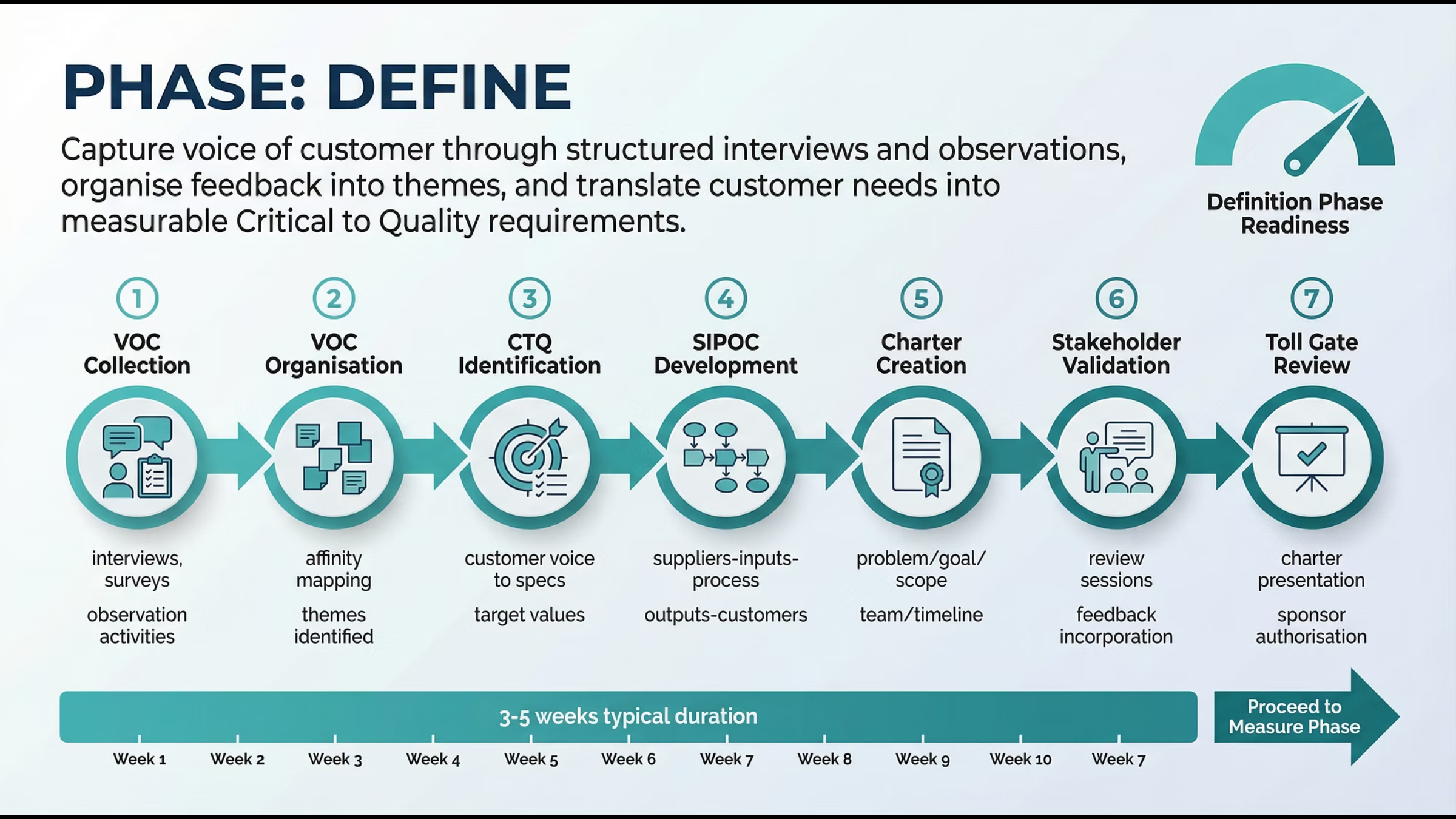

DEFINE

Capture voice of customer through interviews, surveys, and observations. Translate customer needs into measurable Critical to Quality requirements. Build SIPOC diagrams and create comprehensive project charters.

Key Activities

- VOC Collection via Interviews & Surveys

- VOC Organisation & Affinity Mapping

- CTQ Identification & Target Values

- SIPOC Development

- Charter Creation with Problem/Goal/Scope

- Stakeholder Validation & Feedback

- Toll Gate Review & Charter Authorisation

M

Phase 3

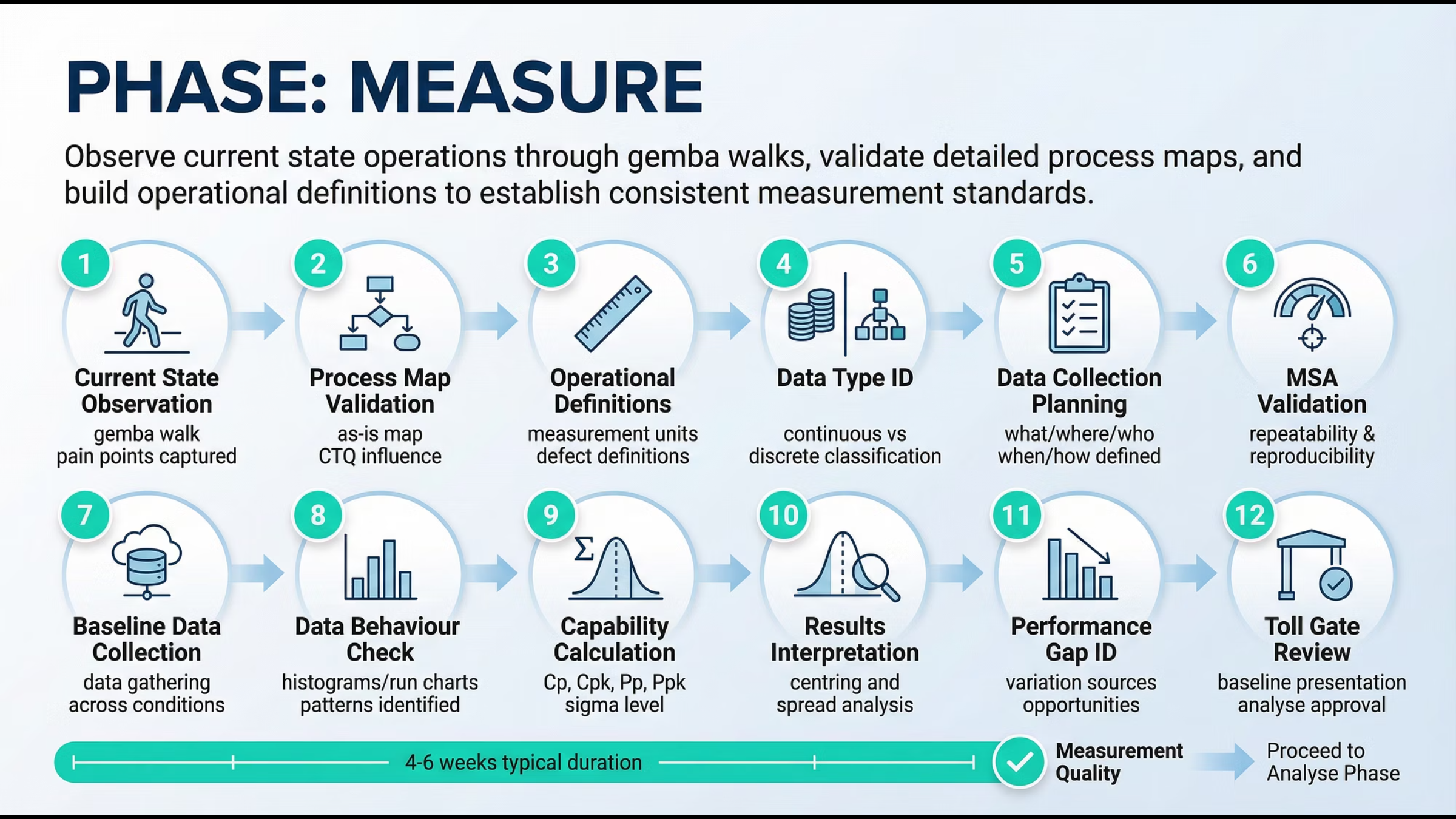

MEASURE

Document current state through process observation and mapping. Develop operational definitions and data collection plans. Validate measurement systems for reliability and calculate process capability metrics.

Key Activities

- Current State Observation & Gemba Walks

- Process Map Validation & As-Is Mapping

- Operational Definitions & Defect Standards

- Data Type Identification

- Data Collection Planning

- MSA Validation for Repeatability

- Baseline Data Collection

- Data Behaviour Analysis

- Capability Calculation (Cp, Cpk, Pp, Ppk)

- Results Interpretation

- Performance Gap Identification

- Toll Gate Review

A

Phase 4

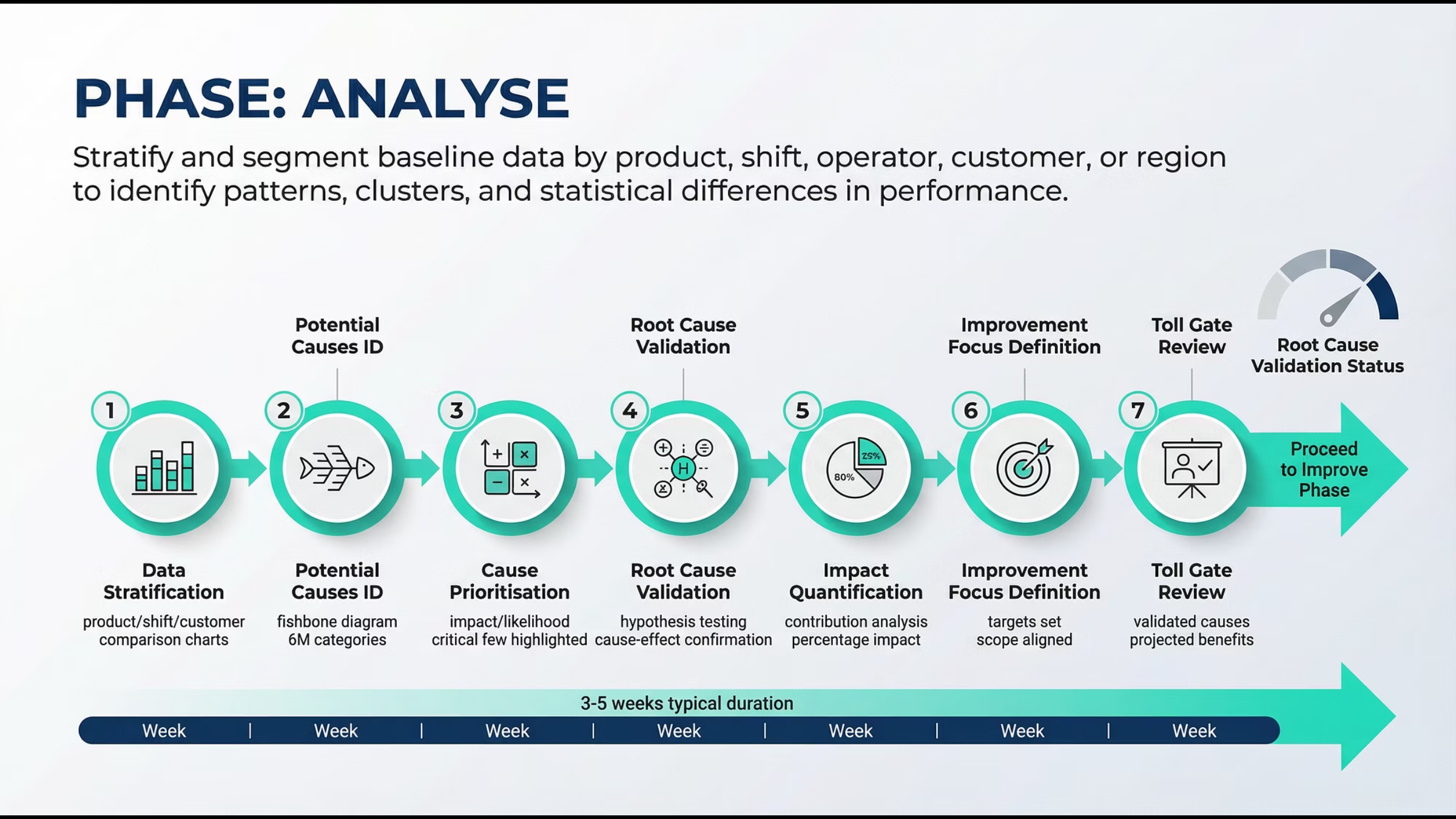

ANALYSE

Stratify and segment data to identify patterns and trends. Generate potential causes using structured methods like fishbone diagrams. Prioritise and validate root causes through testing and data analysis.

Key Activities

- Data Stratification by Product/Shift/Customer

- Potential Causes ID via Fishbone & 6M

- Cause Prioritisation & Critical Few

- Root Cause Validation & Hypothesis Testing

- Impact Quantification & Contribution Analysis

- Improvement Focus Definition

- Toll Gate Review with Validated Causes

I

Phase 5

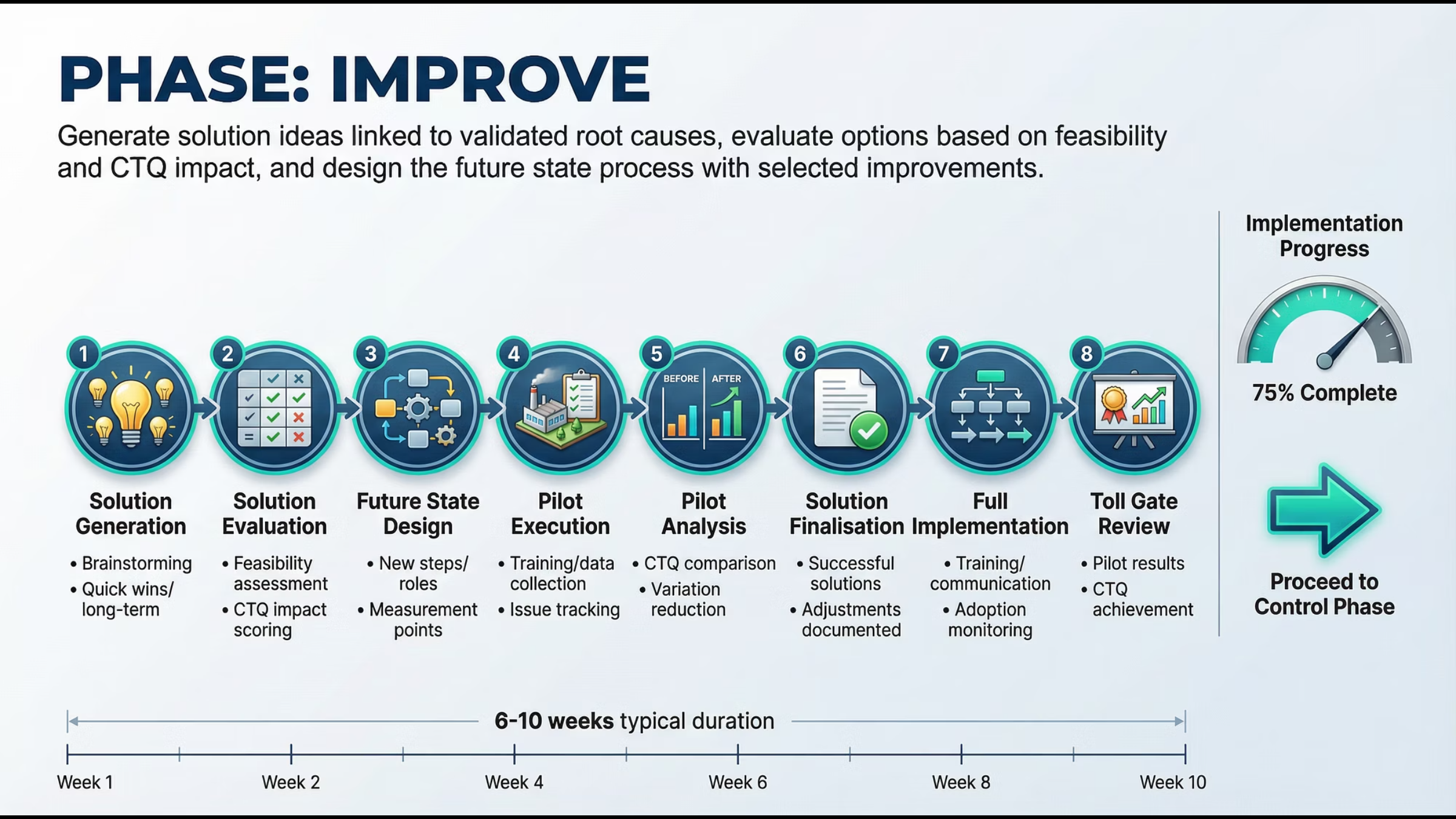

IMPROVE

Generate solution ideas linked directly to validated root causes. Evaluate and select high impact solutions. Design future state processes and pilot solutions in controlled environments before full implementation.

Key Activities

- Solution Generation & Brainstorming

- Solution Evaluation & Feasibility Assessment

- Future State Design with New Steps/Roles

- Pilot Execution & Training

- Pilot Analysis & CTQ Comparison

- Solution Finalisation & Adjustments

- Full Implementation & Adoption Monitoring

- Toll Gate Review with Pilot Results

C

Phase 6

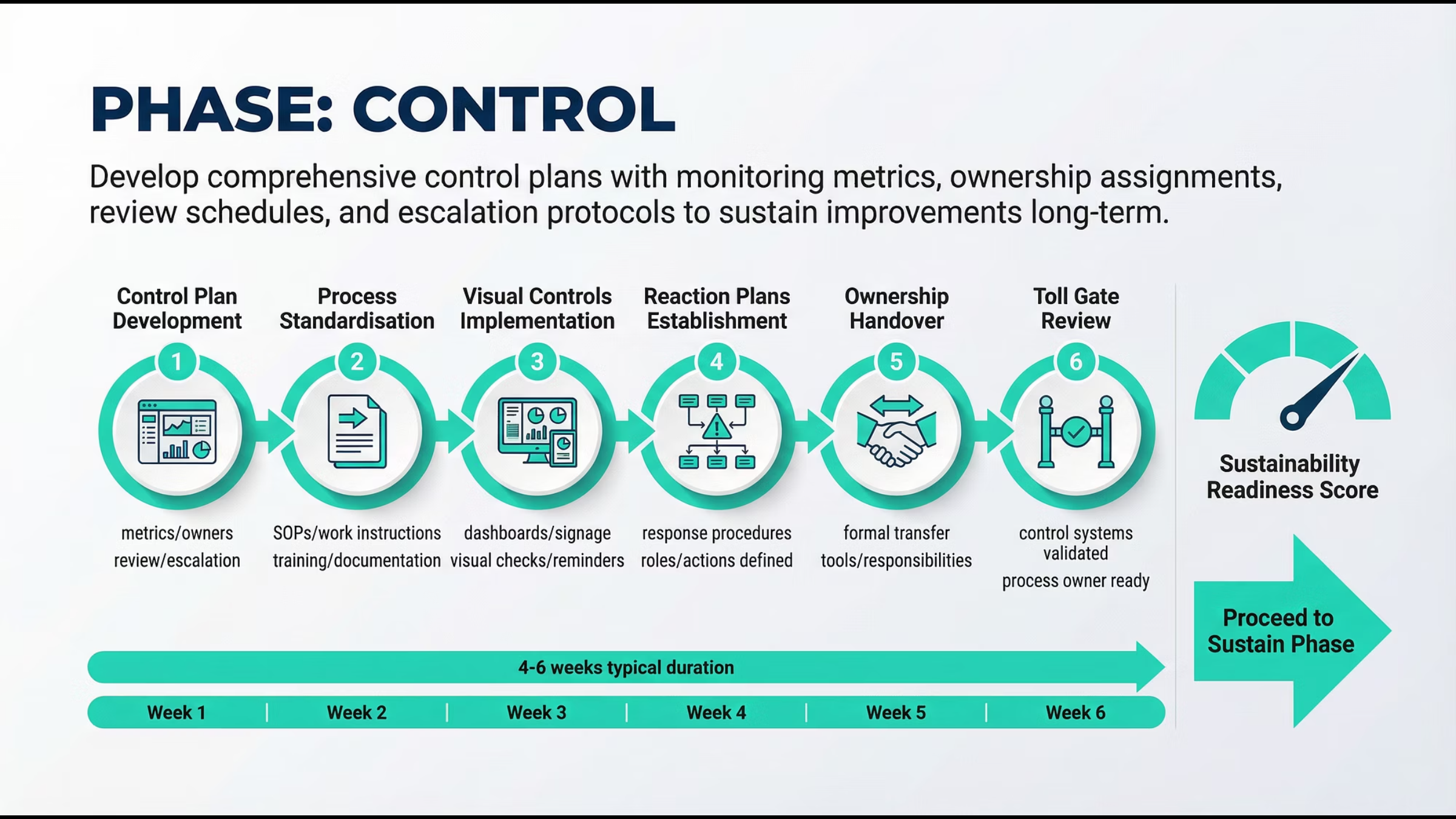

CONTROL

Develop comprehensive control plans with monitoring metrics and escalation triggers. Standardise improved processes through updated procedures and work instructions. Implement visual controls and reaction plans.

Key Activities

- Control Plan Development with Metrics

- Process Standardisation via SOPs

- Visual Controls & Dashboard Implementation

- Reaction Plans & Response Procedures

- Ownership Handover & Formal Transfer

- Toll Gate Review & Systems Validation

S

Phase 7

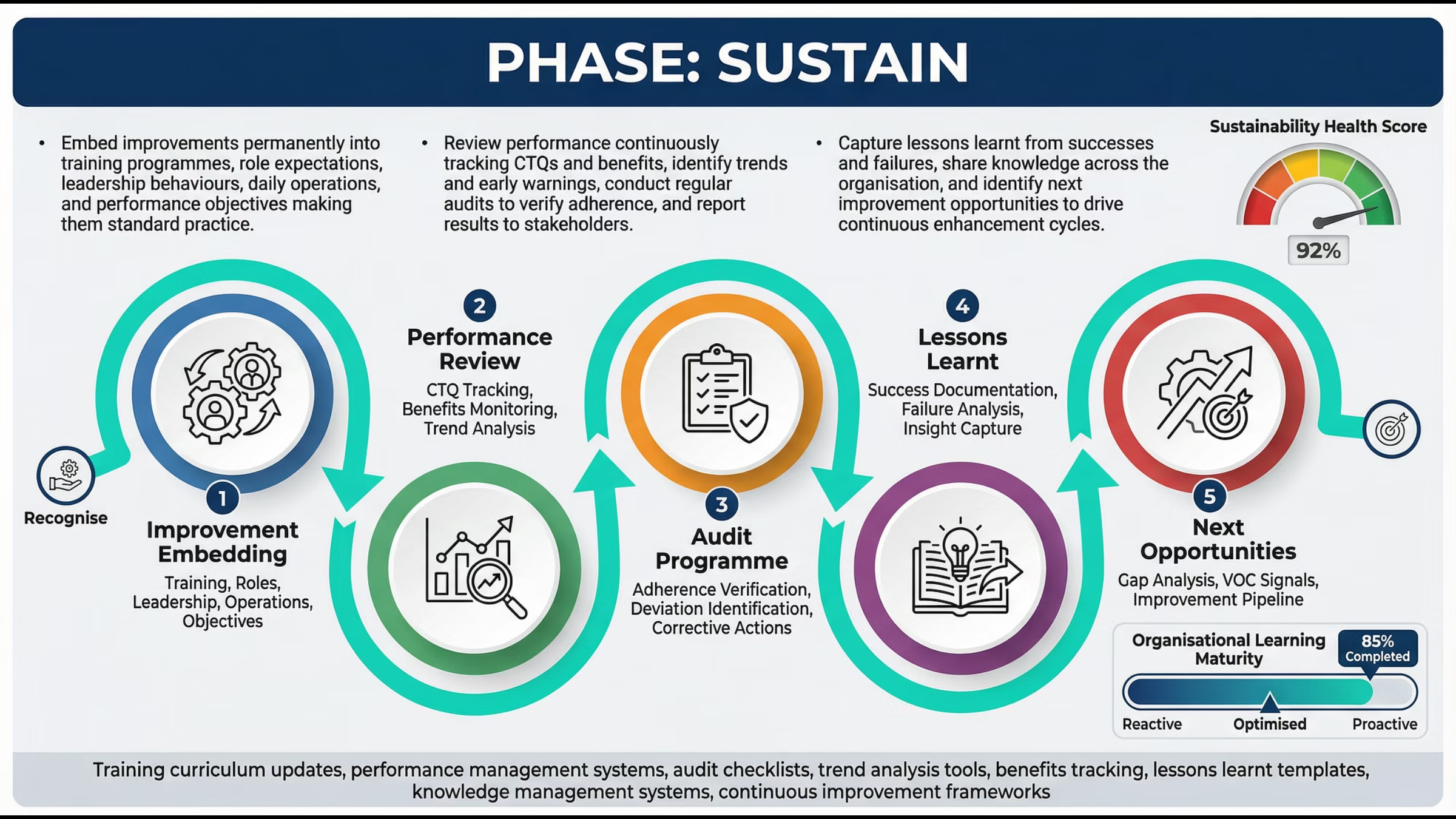

SUSTAIN

Develop comprehensive control plans with monitoring metrics and escalation triggers. Standardise improved processes through updated procedures and work instructions. Implement visual controls and reaction plans.

Key Activities

- Control Plan Development with Metrics

- Process Standardisation via SOPs

- Visual Controls & Dashboard Implementation

- Reaction Plans & Response Procedures

- Ownership Handover & Formal Transfer

- Toll Gate Review & Systems Validation

Why These Reference Cards

What Makes Six Sigma Flash Cards Different

Designed by practitioners for practitioners with real-world application in mind

Complete Lifecycle Coverage

Traditional DMAIC covers only five phases. RDMAICS includes Recognition at the start and Sustain at the end for complete lifecycle management of improvement projects.

Complete Lifecycle Coverage

Traditional DMAIC covers only five phases. RDMAICS includes Recognition at the start and Sustain at the end for complete lifecycle management of improvement projects.

Explanation in each Substep

Every substep card includes explaination what to do, why it matters, and how to execute effectively.

Tool Recommendations

Recommended tools and methods listed for each substep so you always know what to use and when to apply specific techniques.

Visual Framework Descriptions

Visual framework descriptions help you understand how to structure your work with clear diagrams and process flows.

Professional Quality

Recommended tools and methods listed for each substep so you always know what to use and when to apply specific techniques.

Why These Reference Cards

What Makes Six Sigma Flash Cards Different

Whether you’re studying for certification or leading enterprise transformation, these cards provide the guidance you need.

Six Sigma Students

Preparing for Green Belt or Black Belt certification with comprehensive study materials.

Quality Professionals

Leading improvement projects in organisations with structured methodology guidance.

Process Engineers

Executing DMAIC or RDMAICS projects with detailed step-by-step reference.

White to Master levels

Training team members with professional, structured teaching materials.

Operations Managers

Driving continuous improvement initiatives with proven frameworks.

LSS Aspirants

Solving operational problems with structured methodology and clear processes.

Study for Certification

Review substeps systematically across all phases to prepare for Green Belt or Black Belt exams.

Reference During Projects

Check substeps before executing activities to ensure you follow best practices.

Train Team Members

Teach methodology step by step with structured materials that ensure consistency.

Quick Lookup

Access on your device when you need guidance during project work anywhere, anytime.

Six Sigma Complete Reference Cards

The complete RDMAICS framework with 325 cards