Online Lean Six Sigma

Training & Certification

CSSC Accredited courses from White Belt to Master Black Belt. Master process improvement with practical case studies and real-world applications

Accredited by

CSSC

Award Winning

2025 GRA

Certified Professionals

1000+

2025 Global Recognition Award Winner

Lean 6 Sigma Hub has been awarded a 2025 Global Recognition Award for its outstanding contribution to Lean Six Sigma training, enterprise transformation, and educational innovation. This global honor affirms our mission to make continuous improvement practical, scalable, and impactful for professionals and organizations worldwide..

Council for six simga accredited

Lean six sigma Online training offerings

FREE

Lean Six Sigma White belt

kickstart your journey with foundational principles of process improvement with lean six sigma white belt training

$599

LEAN SIX SIGMA YELLOW BELT

Master essential tools and techniques for improving processes and managing small projects.

$799

LEAN SIX SIGMA GREEN BELT

Develop intermediate skills in data-driven decision-making and project management

$1500

lean six sigma black belt

Lead complex projects and drive organizational change with advanced strategies

$3999

lean six sigma master black belt

Learn to mentor Green/Black Belts, drive enterprise capability, and build governance frameworks. Includes real-life case studies, coaching blueprints, and enterprise dashboards.

Build Your Skills in Process Improvement

Learn Lean Six Sigma from beginner to advanced levels with structured self paced online courses designed for real world results.

Learn Lean Six Sigma Through Real World Simulation

Build practical skills with a full end to end case study project designed to mirror real business challenges. Learn by doing with guided examples, dummy data and real analysis tools.

Practical Application

Apply Lean Six Sigma tools to a realistic business scenario and see how each step of DMAIC works in practice.

Hands-On Experience

Work through an interactive case study with dummy data, charts, templates and worked examples.

Data-Driven Decision Making

Learn how to collect data, analyse results and make informed decisions using real project steps.

Teams Perspective

Understand how roles like process owners, analysts and project leaders work together during improvement projects.

Performance Insights

See how improvements impact cost, quality, delivery time and customer satisfaction through measurable results

Built for Self Study

All content is designed for independent learning with clear explanations, structured steps and visual guides.

Explore an End to End Lean Six Sigma Black Belt Project

Follow a complete DMAIC project from Define to Control using a fictional but realistic business problem. See exactly how decisions are made, what tools are used and how improvements are delivered.

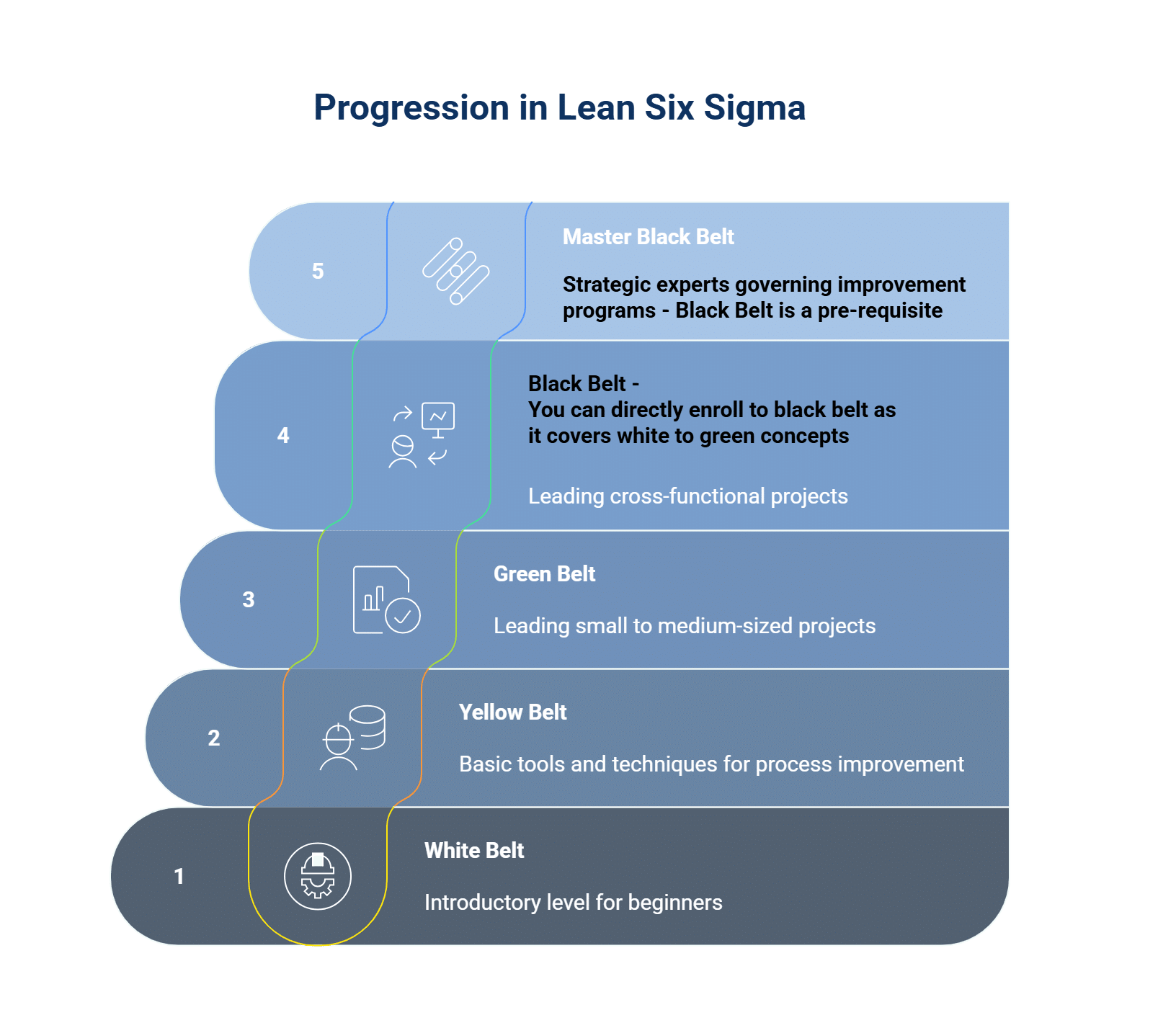

Progression in Lean Six Sigma

Learn how each belt level builds your skills in problem solving, data analysis and process improvement. All courses are self paced and designed for online study.

White Belt

Introductory level that builds awareness of Lean Six Sigma principles, waste types, and the DMAIC framework. Ideal for beginners and front-line staff.

Yellow Belt

Covers basic tools and techniques used in process improvement. Yellow Belts support project teams with data collection and problem-solving.

Green Belt

Focused on leading small to medium-sized projects. Green Belts apply DMAIC, use statistical tools, and drive improvements within their function.

Black Belt

Advanced level for professionals who lead cross-functional projects. Black Belts use complex analytics, mentor Green Belts, and drive enterprise-level change.

Master Black Belt

Strategic experts who train and coach Belts, govern improvement programs, and align Lean Six Sigma with business goals at the enterprise level.

WHAT IS LEAN SIX SIGMA?

Lean Six Sigma is a proven method for improving processes, reducing waste and solving problems using data. It combines Lean principles that focus on speed and efficiency with Six Sigma techniques that focus on quality and reducing variation.

Improves Business Efficiency

Identify and remove non value added activities across any process to improve speed and performance.

Reduces Errors and Variations

Use the DMAIC framework and simple data tools to deliver more consistent, reliable results.

Boosts Career Growth

Lean Six Sigma certified professionals are valued across industries including healthcare, logistics, finance, IT and service.

Builds a Problem Solving Culture

Helps teams use a structured method to understand problems, test solutions and sustain improvements.

Award Winning

2025 Global Recognition Award Winner

Global Accreditation

Accredited by the Council for Six Sigma Certification

Online Training

100% self-paced online learning options

1000+ Trained

1,000+ professionals certified globally

Why Choose Lean six sigma online training from Lean 6 Sigma Hub?

Get accredited, flexible and practical Lean Six Sigma training designed for self paced online learning. Learn real tools, apply them immediately and gain certification trusted around the world.

Lean 6 Sigma Hub delivers online Lean Six Sigma training focused on real world problem solving. Each course uses practical case studies, dummy data and step by step examples so you can learn by doing, not by memorising theory. You can study at your own pace and gain a certification that is recognised globally across industries.

What Our Learners Say

News & Resources

How to Handle Resistance During the Sustain Phase: A Comprehensive Guide to Long-Term Change Management

The Sustain phase represents the critical juncture where lasting organizational change either takes root or withers away. This comprehensive guide explores proven strategies for handling resistance during this crucial period, including monitoring systems, accountability structures, and culture-building techniques that ensure improvement initiatives deliver long-term results rather than temporary gains.

How to Handle Resistance During the Sustain Phase: A Comprehensive Guide to Long-Term Change Management

Implementing process improvements is one thing; sustaining them over time is an entirely different...